Injection Moulding

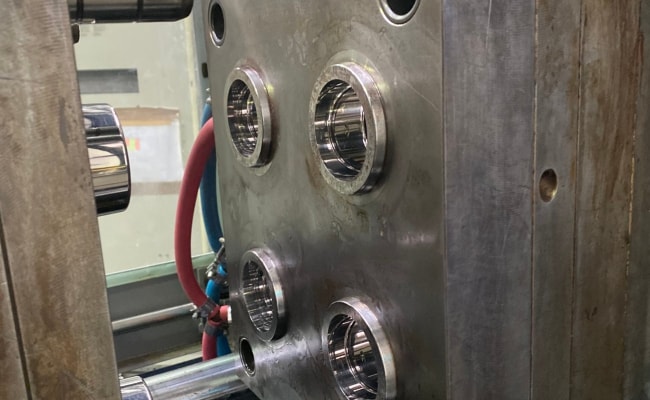

Injection moulding is a complex manufacturing process whereby plastic pellets are melted down and then injected into the tool to fill the cavities, which make the tool impression. Once the plastic has taken shape of the cavity, it is then cooled and hardens.

Injection moulding provides a better and stronger finish by achieving closer tolerances on intricate parts and patterns.

What We Offer

In determining which one of our injection moulding or thermoforming machines is best for your particular product, we consider the following issues before proceeding with production:

- Production quantity

- Design & Engineering requirements

- Time frame

- Tooling size

- Required finish

This ensures we maximise production, reduce waste & offer you the most cost effective process for your product.

We are committed to reducing our waste

All our skeletal waste is sent back to the manufacturer to be recycled & reused ensuring our waste plastic is kept to a minimum.